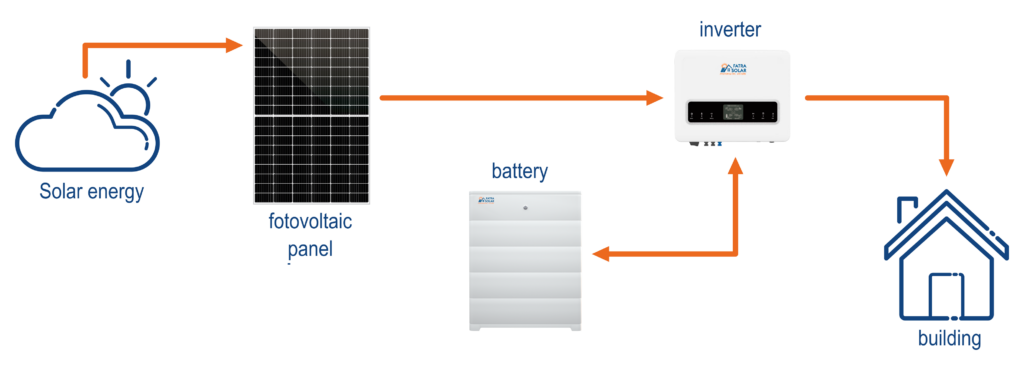

Elements of a Photovoltaic System

Photovoltaic panels

Lifespan of Photovoltaic Panels

Types of Panels – Monocrystalline and Polycrystalline

Monocrystalline Panels

Polycrystalline Panels

A solar power plant made from these panels has more consistent performance. These panels are better suited for locations with some deviation from ideal orientation. In general, polycrystalline panels have slightly better efficiency with solar radiation at various angles.

Mounting system for a flat roof – in this case, the aluminum support structure was mounted on threaded rods anchored into the reinforced concrete structure of the roof. The panels were installed in a “horizontal” position.

Mounting system for a sloped roof – in this case, the support structure was mounted into the wooden battens under the metal roofing.

Mounting system for a flat roof – in this case, the aluminum support structure was mounted on threaded rods anchored into the reinforced concrete structure of the roof. The panels were installed in a “horizontal” position.

Mounting system for a sloped roof – in this case, the support structure was mounted into the wooden battens under the metal roofing.

Mounting Structure for Photovoltaic Panels

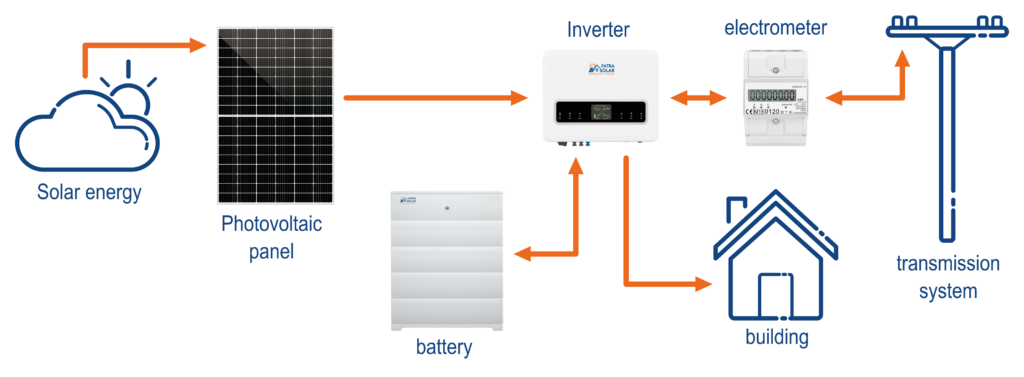

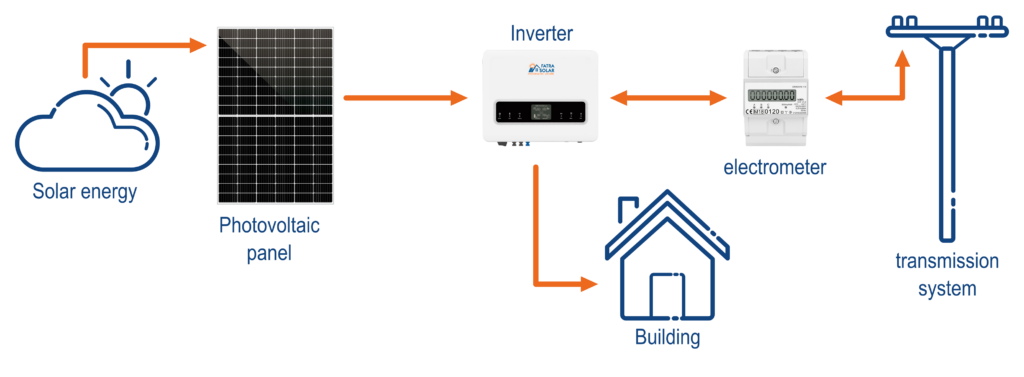

Inverter

The electric current generated by photovoltaic panels is direct current (DC). However, in family houses, we use alternating current (AC), which is necessary for operating devices with electric motors.

The conversion of DC electricity produced by photovoltaic panels to AC is done by inverters. Therefore, the inverter is a key component of a photovoltaic power plant.

In addition to converting electrical energy, many high-quality inverters offer the ability to monitor performance in real time as well as control the photovoltaic power plant remotely via a mobile application. They just need to be connected to the internet and configured.

Some manufacturers offer “all-in-one” devices that not only convert current to AC but also include a battery charger, solar regulator, color monitor, remote management, and more, simplifying the entire installation.

Inverter Performance

Single-phase or Three-phase Inverter

Batteries

Battery Capacity

Batteries have their capacity indicated in ampere-hours (Ah) and their operating voltage in volts (V). The appropriate size must be aligned with the output of the panels, the inverter, and how we use the photovoltaic system. For family houses, the capacity typically ranges from 2 kWh to 8 kWh. The voltage of batteries is usually 12V, 24V, or 48V. The higher the battery voltage, the lower the losses on the cable connections between the inverter and the battery.

To estimate how much electrical energy we can get from a battery, we need to multiply the operating voltage by its capacity. For example, if a battery with a typical operating voltage of 12V has a stated capacity of 200Ah, such a battery will deliver approximately 12V x 200Ah = 2,400Wh = 2.4 kWh of electrical energy. However, this calculation is only approximate and does not account for various factors such as the changing operating voltage of the battery during discharge and so on.

Types of Batteries

LiFePo4

Lithium iron phosphate (LiFePO4) batteries do not need to be fully charged, partial charging is sufficient, which is their main advantage over lead-acid batteries. Additionally, their capacity and lifespan are not as dependent on temperatures. They have a high cyclic lifespan and can be discharged to 20% of their total capacity (80% discharge) without significantly affecting their lifespan. They typically handle 5,000 cycles. Moreover, they can provide a relatively large amount of energy without damaging the battery, which is advantageous for sudden high energy demands. They have a high energy density, meaning they contain a relatively larger amount of energy per kilogram of their weight compared to the aforementioned batteries. Along with Li-Ion, they are currently the best types of batteries for photovoltaic systems.

Li-Ion

They are very similar to the aforementioned LiFePO4 batteries.

Životnosť batérie

Batteries in photovoltaic systems are subjected to cyclic loads (one cycle is one charge and discharge). Manufacturers typically specify the number of cycles as the battery’s lifespan. This allows us to estimate the lifespan in years quite accurately. For example, if we charge and discharge the battery on average once a day, then a battery with a specified 5,000 cycles will theoretically last 5,000/1 cycle per day/365 days per year = 13 years.

For optimal battery lifespan, the ambient air temperature is also important and should ideally be around 20°C. At such temperatures, the self-discharge rate is relatively low (2%). At -10°C, it decreases by approximately 20-25%.

Types of Photovoltaic Power Plants

Pripojené na sieť (On Grid)

These are systems connected to the regular distribution power grid. When electricity is needed, the electricity generated by the photovoltaic power plant on the house is used first, and if it is not enough, the remainder is supplemented from the standard power grid. Such a system does not include a battery.

In the event of a power outage from the distribution company, the photovoltaic power plant also shuts down for safety reasons – to prevent accidental electricity from flowing into the distribution network.

– Disadvantage: Lower utilization of generated electricity because daytime surpluses cannot be stored in a battery for later use in the evening.

+ Advantage: Lower cost compared to systems with a battery.

Island Systems (Off Grid)

These are standalone systems without connection to the power grid, hence they are called island systems. Such a system must include a battery to store the electricity generated during the day, which is then used when the sun is not shining. However, in Slovak conditions, such a solution is insufficient for heating an average family house in winter and usually not enough for year-round water heating. With proper sizing, an off-grid system could meet all other household electricity needs. This system is suitable for cottages or remote buildings that require smaller amounts of electricity.

– Disadvantage: Higher initial investment and the need for a backup electric generator for periods without sufficient solar radiation.

+ Advantage: Independence from the public power grid and maximum utilization of the generated electricity.

Hybrid Solar Systems (Combination of On Grid and Off Grid)

These are systems connected to the regular distribution power grid. When electricity is needed, the electricity generated by the photovoltaic power plant on the house is used first, and if it is not enough, the remainder is supplemented from the standard power grid. Such a system includes a battery, which then serves as a source, for example, when the sun is not shining or in the event of a power outage (it then switches to off-grid mode).

– Disadvantage: Higher initial investment.

+ Advantage: Independence from the public power grid and maximum utilization of the generated electricity.

Virtual Batteries

Since batteries are usually the most expensive components of a photovoltaic power plant, some electricity suppliers have come up with the offer of a so-called virtual battery. This is a fictional storage of electricity, which works in such a way that during times of excess electricity produced by photovoltaics, this surplus is credited to your account with the electricity supplier. Later, when there is a shortage of electricity from photovoltaics, you can draw the same amount from the distribution network for free or at a reduced rate. These solutions often require that the entire photovoltaic system be supplied and installed by the respective distribution company. Another pitfall can be that, even though electricity from the virtual battery may be free, you will pay the transmission fee twice (once for sending it to the grid and then for drawing it from the grid).

Therefore, it is always recommended to thoroughly study the specific conditions.

Performance - What to Expect from Photovoltaics

Installed Capacity

The performance of a photovoltaic power plant is measured in kWh. The basic data is the so-called installed capacity (or in other words, the maximum output under ideal conditions). This is the sum of the outputs specified by the manufacturer on the photovoltaic panels. One photovoltaic panel typically has a capacity of 300 Wp (Watt peak). If we have 12 such panels on the roof, the total installed capacity of our photovoltaic power plant will be 12 * 300 = 3,600 Wp = 3.6 kWp. This setup will therefore ideally produce 3.6 kWh in 1 hour.

Actual Performance

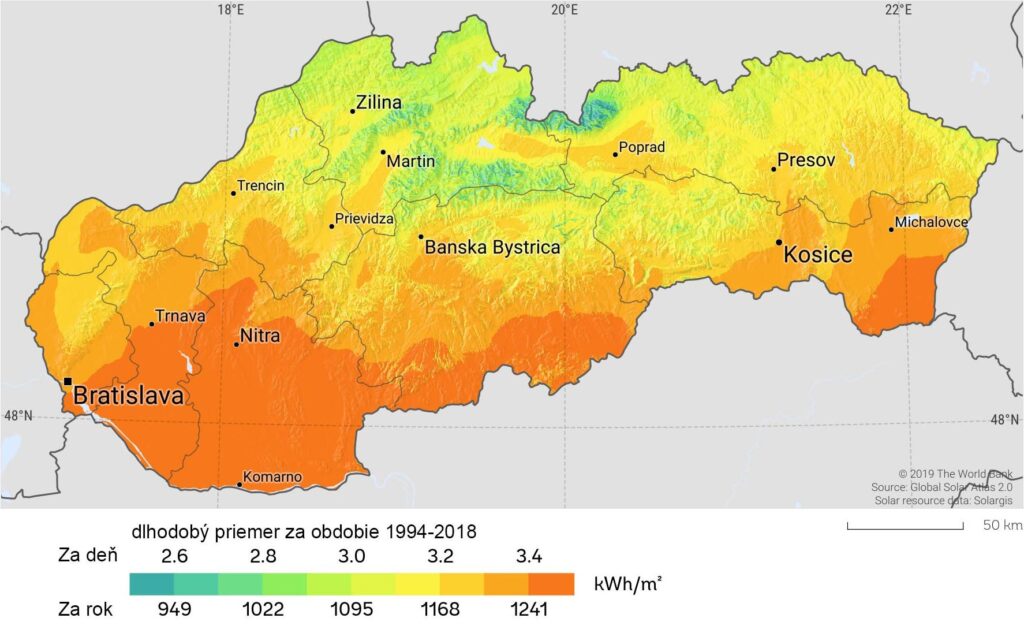

Skutočný výkon fotovoltaickej elektrárne závisí najmä od intenzity slnečného žiarenia ako aj jeho trvania. Priemerný ročný úhrn slnečného žiarenia v kWh/m2 udáva tabuľka nižšie. Treba mať na pamäti, že fotovoltaické panely majú obvykle veľkosť 1,0×1,5m = 1,5m2 plochy. Takisto si je potrebné pozrieť účinnosť panelu, ktorý udáva každý výrobca. Napríklad v Bratislave by panel o rozmere 1,5×1,0m a účinnosti 18% dokázal za rok teoreticky vyrobiť 324 kWh (1200kWh/m2 x 0,18 x 1,5 m2 panelu).

Image source: The World Bank, Global Solar Atlas 2.0, data and map are from http://solargis.info.

From the theoretical performance, it is necessary to deduct losses due to the angular reflectivity of the panels (around 3%), losses due to ambient temperature (up to 7%), losses in cable distributions (depending on their length), and losses from converting direct current to alternating current (around 10%). Therefore, it is common to account for about 20% losses from the generated electricity.

Performance Across Regions of Slovakia

Regarding the specific placement of a photovoltaic power plant within Slovakia, we can state that the most solar radiation falls throughout the year in southern Slovakia, while the least falls in Orava and Kysuce. The difference in the amount of solar energy received between the coldest and warmest regions is only about 15%. For this reason, a photovoltaic power plant makes sense even in the colder areas of Slovakia. For a simple calculation, we can consider that under Slovak conditions, 1 kWp of installed capacity can produce 1000 kWh per year. The question, of course, is whether we can continuously utilize this energy or how much of it we can store in a battery for later use. To ensure the photovoltaic power plant has the highest possible performance, it is necessary to ensure the optimal orientation of the panels.

Ideálna orientácia a sklon

Ideálna orientácia panelov je presne na juh pod sklonom 30-40°, pričom by nemali byť tienené žiadnymi predmetmi počas celého dňa. Je dobré vedieť, že aj keď panely nemôžu mať ideálnu orientáciu priamo na juh, ale sú umiestnené priamo na východ alebo západ, ich účinnosť je nižšia len približne o 14%. To isté platí aj pri rozdieloch v sklone, pokiaľ máme o 15 stupňov menší sklon ako 30°, alebo väčší ako 40°, výkon panelov býva menší len o pár percent (okolo 5-6%). Väčší rozdiel urobí to, či ich máme mierne zašpinené alebo úplne čisté.

Weather and Photovoltaic Performance

In cloudy weather, output drops to approximately 50%, and in heavily overcast conditions, it can drop to as low as 10% of maximum values. During the winter months, only about 20% of the electricity is produced compared to the summer months. If the panels are covered with a continuous layer of snow a few centimeters thick, their performance typically decreases to 5-10%. Snow usually doesn’t stay long on the slippery surface of the panels, so unless the panels are located in an area with heavy snowfall, this shouldn’t pose a problem.